Anodes or impressed current in combination with ZINGA

The pdf document explains specifications of ZINGA in combination with (Zinc) anodes or impressed current systems.

The pdf document explains specifications of ZINGA in combination with (Zinc) anodes or impressed current systems.

Information given in this document is complement to the technical specifications given in the technical data sheet of ZINGA.

This document describes general guidelines for ZINGA on welding and welding on ZINGA.

ZINGA can be overcoated with a topcoat to give a coloured finish to the structures. Like all porous Zinc rich coatings, care should be taken to ensure compatibility of the topcoat with ZINGA.

Under practical conditions, we advise the use of a sealer to avoid any problems with the compatibility of the topcoat. Zingametall offers two compatible sealers which have been tested according to ISO 12944: Zingalufer (PU sealer) and Zingaceram HS (EP sealer).

It is not possible to give an extensive list of products which are or are not compatible with ZINGA. Every topcoat has its specific characteristics which make compatibility on ZINGA more or less likely.

We can only give general guidelines to detect whether or not it is likely that a topcoat is suitable for use on ZINGA or not.

Listed characteristics below can give a good indication on the compatibility for ZINGA.

Water based products can cause formation of Zinc salts underneath the topcoat, resulting in bad adhesion. Water based coatings should not be used on top of ZINGA.

If a topcoat is used directly onto ZINGA, it is advised to always perform a small test application on a test plate. This prevents problems on a big structure and also gives the applicator the chance to get to know the product.

For more information, please contact the Zingametall Technical Team.

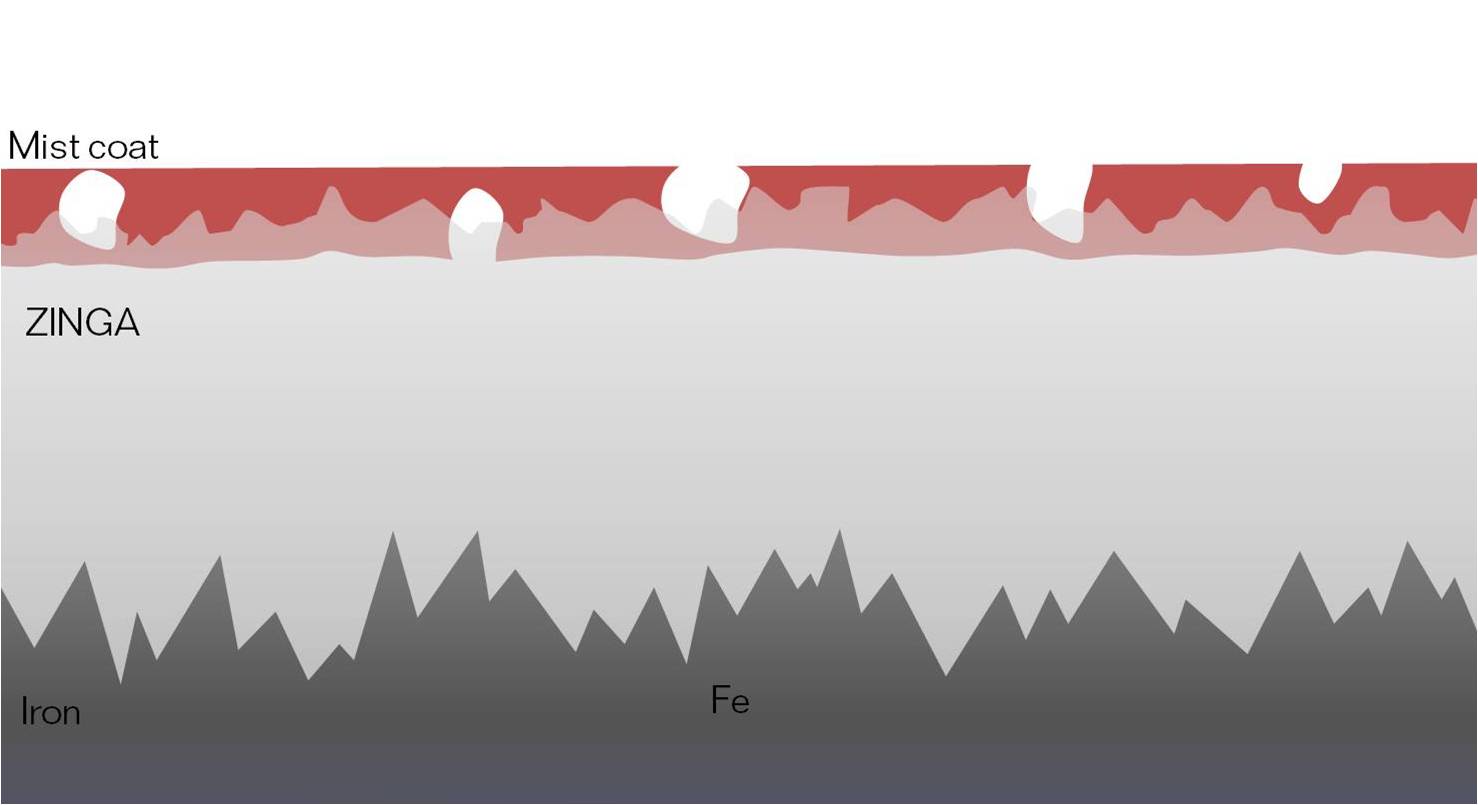

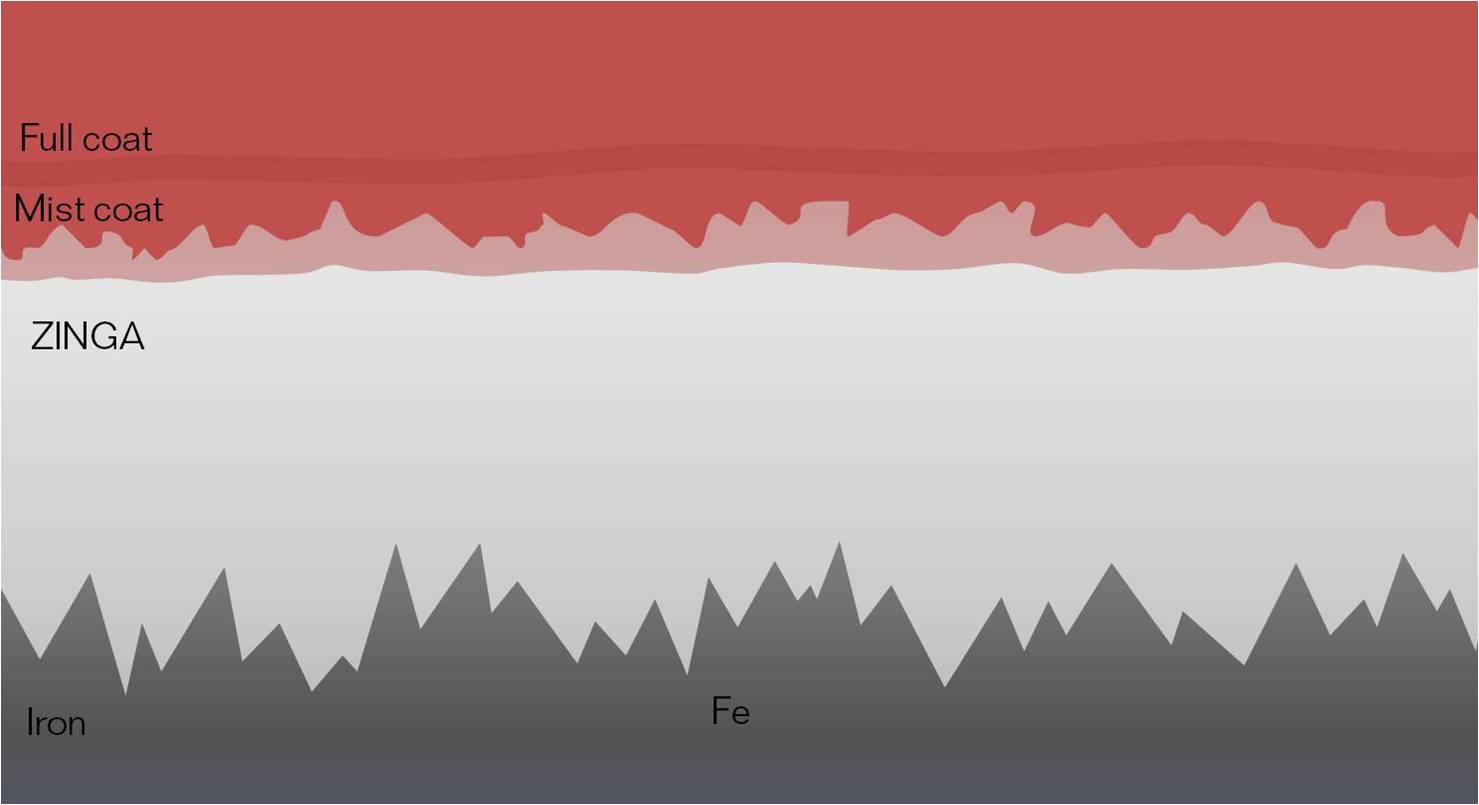

To avoid bubbling of a topcoat or sealer over ZINGA, we advise to apply the paints using a mist/full coat technique.

A thin coat of sealer or topcoat is applied over the surface of ZINGA before a full pass of the coating at the normal film thickness. This thin film penetrates only the surface layers of the ZINGA and seals its surface. Also relatively porous, the mist coat presents little obstacle to the passage of air from these upper layers.

First, a thin continuous layer is applied which gives air bubbles easy passage through the film. The first mist coat also provides a barrier for aggressive solvents in the topcoat.

Application at least 4 hours after ZINGA is touch-dry.

25 to 30 μm DFT (continuous layer).

Normal dilution according to the technical data sheet.

Application at least 2 hours after the mist coat is touch-dry.

Specified layer thickness minus 25 to 30 μm DFT (of mist coat).

Normal dilution according to the technical data sheet.

This document describes the technical background of the reason for applying a topcoat with a mist/full coat technique and also the specifications to do so.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |